cover closure flow test c-sump carbon seal|sealing sump pump pit cover : manufacturer The environment a seal will be exposed to is crucial when selecting the design and material. There are a number of key properties that seal materials need for all environments, including .

Installing MAME; Compiling MAME; Configuring MAME; Basi.

{plog:ftitle_list}

webVem pro vip 👇. @MAGODOVIP. 1.7k 0 3 1. Vazados 2023 (O retorno) 26 Feb, 03:25. 🔱COMPLETO NO VIP🔱. ⚠️GRUPO VIP VAZADAS⚠️. 💰🤑20 reais vitalício. 📽 VÍDEOS VAZADOS 📽.

Nomenclature: COVER - CLOSURE FLOW TEST - C-SUMP CARBON SEAL. Engine OEM: GE. Engine Applicability: GENX

Seal Quality Tests. Passing SQT ≠ leak-free package. Examples. Heat seal strength. A pouch with a strong heat seal peel force may have a pinhole in the pouch face. Closure application . For best results with double (or tandem) seals handling abrasive, the inboard seal faces should be a hard material, such as silicon carbide vs. silicon carbide, while the outboard .

Sump covers should be made of durable plastic or other rigid material and designed for airtight sealing with a built-in gasket. The sump pump lid should have built-in air-sealing grommets .

Take these steps to effectively seal your sump pump cover: Use a foam rubber gasket between the cover and the floor. Apply silicone caulk around the edges of the cover. Seal any .The environment a seal will be exposed to is crucial when selecting the design and material. There are a number of key properties that seal materials need for all environments, including .Concrete sump pump covers are a popular choice among homeowners due to their durability and ability to effectively contain odors and noises generated by sump pumps. These covers .

Simply understanding a mating surface’s R a, or roughness average value, is not enough to properly specify the surface finish because it is entirely possible to have very .By the end of this course you will understand and can identify: The purpose of the mechanical seal. The essential elements of a mechanical seal. The classification of mechanical seals. . Mechanical seals serve an important purpose—to seal fluid within a vessel where a rotating shaft passes through a housing. The engineering that goes into mechanical seal design can be complex. Since mechanical seals .

Maintaining container closure integrity (CCI) is challenging for vials that are packaged at room temperature and stored and/or transported at a colder temperature, such as -80°C. Cold temperatures can affect the sealing mechanisms of the package due to the glass transition temperature (-50 to -70°C) of the rubber stopper used to seal the vial and the .Welcome to our comprehensive guide on mechanical seals, an essential component in many industrial applications. Whether you're an experienced engineer or new to the field, understanding the intricacies of mechanical seals . Sealing a sump pump cover is a crucial step in maintaining a healthy and safe basement environment. By properly sealing the sump pump cover, you can prevent. . it. Begin by thoroughly cleaning the sump pit, removing any debris or obstructions that could interfere with the seal. Next, place the cover over the sump pit, ensuring that it fits . Seal The Cover It’s imperative that you seal the sump cover properly, or water and gas can still seep out. Place the foam sealant/gasket underneath the wood and push it down into the ground firmly until it holds. This should seal it properly, but you should still be able to lift it off easily if you need to access the pump.

This article will explain what a mechanical seal is and the key design features that make them work. Basics of fluid pump sealing. A mechanical seal is simply a method of containing fluid within a vessel (typically pumps, mixers, etc.) where a rotating shaft passes through a stationary housing or occasionally, where the housing rotates around the shaft.• Pump in series without seal failure from elevated inlet pressure. • Provide full CIP service without dismantling. (Models equipped with type D, DG, E and F seals). INTEGRAL CLEAN-IN-PLACE DESIGN Series C and SP Pumps are available with Tri-Clover's “Groove-in-Shaft” design (D, DG, E and F seals) for use in CIP installations.

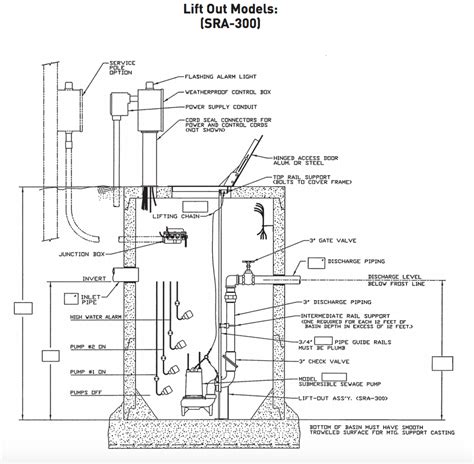

seals for wastewater pumps

Carbon seal, born in 1967 in NASA, 3 is widely used for gas and liquid applications. The leakage characteristics of carbon seal situates between labyrinth seal and mechanical seal. 4 Comparing with the labyrinth seal, pointed out by P&W, 5 air leakage of carbon seal could be reduced by at least 60%. Results given by GE 6 proved further that air leakage of carbon seal .Why Test For Radon? Radon and Real Estate; . Clear Sump Cover w/seals Clear Sump Cover w/seals $ 70.97. Clear Sump Cover w/seals, Clear Lexan, 4″ TY Seal, Cord Grommet, 1.5″ ejection pipe seal. . EZ FLOW VALVE LARGE $ 28.75 Add to cart; Rubber Seal, 1.25 in.Pipe Sump $ 2.90 Add to cart; PRODUCTS.°C-30 -20 -10 0 10 20 30 40 5W-30 10W-30 SAE 30 Kohler PRO 10W-50 FUEL RECOMMENDATIONS WARNING Explosive Fuel can cause fi res and severe burns. If a gaseous odor is detected, ventilate area and contact an authorized service technician. LPG is extremely fl ammable and is heavier than air and tends to settle in low areas where a spark .Fits 18″ basins; Designed to work with several popular pumps; Comes with additional bolts and widgets to fit different sizes; Easy to install; See Cover This Parts2O Cover is one of our favorite covers for 18″ diameter basins. It has several widgets to get a tight seal, and the cover is well-made and built to last many years.

how hard is the njgpa test

10 Methods How to Seal Sump Pump Cover for Radon 1. Install a Radon Mitigation Sump Cover. The most effective way to reduce the risk of radon entering your home is to install a radon mitigation sump cover. This cover seals the sump pump lid and prevents air from entering the house through the lid.Using a properly sealed sump pump cover can help reduce the risk of radon leakage into the home. How Sump Pump Covers Help With Radon Mitigation. A properly sealed sump pump cover can be an effective part of a radon mitigation strategy. It helps prevent radon from entering your living space through the sump pit.

Single mechanical seal - this is the most common seal type used which is a seal used to seal the pump head, ensuring the liquid is retained within the pump head and does not leak out via the back of the pump casing where entry is made via the shaft which is driven by a motor. The seal consists of several parts involving a rotating assembly .

how hard is the nmls test to pass

seals for sewage pumps

4. Use a Sump Pump Cover. Installing a sump pump cover is one of the better and simpler ways to hide a sump pump. Many sump pumps come with stylish covers in addition to functional ones. However, sump pump . Shaft finish, hardness, and material are not critical. The seal can handle a wide variety of fluids, pressures up to 3000 psi, speeds to 50,000 rpm, and temperatures from -425-1200 F. This type of seal has become popular on pumps where leakage is not allowed. Radial lip seals are primarily used to retain lubricants and exclude contaminants.What Is a Sump Pump Cover? A sump pump cover, on its most basic level, covers and seals the sump pump and pit. There are different types, depending on the sump pump type. Covers for Submersible Sump Pumps. As the name .

COVER - CLOSURE FLOW TEST - C-SUMP CARBON SEAL: RQST* We do not currently have a manufacturing solution for this item but will do our best to source it. 11C3439: FIXTURE - PROTECTOR/INSTALLATION-NOZZLE COVER - FWD OUTER SEAL: RQST* We do not currently have a manufacturing solution for this item but will do our best to source it. 22658G - 01

Seal, and now the Ring & Seal operation of SKF, making SKF a “go to” supplier for today’s and tomorrow’s program needs. Bearing compartment carbon seals SKF carbon seal designs are engineered to seal the main shaft bearing compartment and oil sump, for more eficient and environmentally sustainable operation. The oil sump, also known as the oil pan, acts as a reservoir to store and protect your vehicle’s oil. . Overtightening the oil filter during an oil change can damage the seal and lead to leaks. Faulty valve cover: Excessive heat, pressure, or impact can all cause a valve cover to become warped or damaged. This can compromise the seal .The OD of the seal face may not even show contact. Is there a flush? Does the flush really flow all around the seal faces? Figure 4. ID Wear Track. When using two hard faces, a seal may not have very much pressure induced distortion and thermal effects may be more prevalent.

Viton, HNBR and explosive decompression-resistant materials grades are also available. Temperature range is -45°C to +210°C according to the elastomer specified. Hydrostatic Testing. Normally carried out as part of the final vessel test but an individual closure hydrotest can be provided as an option. Unique Seal with Integral Anti-Extrusion .

Mechanical face seals are a complex combination of materials and design that form a system whose prime objective is maintaining the integrity of the pumping system, keeping what is inside where it belongs and preventing contamination from the outside. From the simplest design to the most complex, the system must operate across a multitude of conditions (and .the molded shape elastomeric seals 5. Can produce high forces against mating hardware The molded in place sealing element, Gask-O-Seal or Integral Seal, represents a significant improvement over both the flat gasket and the molded shape in a groove for near zero leakage static sealing: Gask-O-Seal Features and Benefits: 1.

Ampco # KIT#3-C114-E AC Series Seal Kit includes Seal Carbon, Seal O-Ring, Spring D Seal, Cup D — Use with C-114/C-214 Pump Models. (262) 784-3340 | SALES . Sun-Flow; Texcel; Tudertechnica; Filtration. Glasfloss Industries; Global Filter; Kaydon Filtration; Pentair; Shelco Filters; Solberg Filtration; General Process Equipment. The other seal, seals the rotating component(s) to the shaft (it normally moves axially on the shaft or shaft sleeve) A spring member to maintain face contact, such as a single spring, multiple springs or metal bellows. Other mechanical seal hardware, which includes shaft sleeves, gland rings, collars, compression rings, and/or pins.Our double-seal design keeps your sump completely dry. Application - Eliminates leaking polyethylene and fiberglass sump covers without breaking concrete. Features - Installs in minutes Rugged stainless steel ring and cover for maximum strength Mechanical seals insure maximum life and tightness Field Adjustable Clamping device

sealing surfaces for wastewater pumps

Clique no botão “Gerar Novo Sinal” para que o gerador Fortune Tiger gere novas coordenadas. Você receberá o número de jogadas normais e Turbo, assim como o minuto. A partir do seu minuto atual, jogue as rodadas normais seguidas das Turbo. Caso ultrapasse o horário máximo definido no gerador de sinais Fortune Tiger, gere um novo .

cover closure flow test c-sump carbon seal|sealing sump pump pit cover